Our Technology

Leading the way.

We are one of the few companies worldwide with a patent-pending technology capable of transforming plastic waste into precursors and carbon in a single, zero-waste, and pollution-free step. Our technology distinguishes itself from conventional pyrolysis by focusing on producing valuable feedstock for virgin plastics rather than crude oil or other low-value outputs.

Our technology is built for the circular economy. By extract liquid feedstock from discarded plastics, we can make new, virgin-grade plastics without ever needing fossil fuels again. A truly circular process.

The Three-Step Process

-

1. Sublimation

Solid plastic waste is heated in a kiln using electricity, converting it into a gaseous state in a sublimation-like process.

-

2. Condensation

The gases are then rapidly and intelligently condensed as per our proprietary algorithms.

-

3. Distillation

An in-line distillation process results in plastic precursors, polyolefins and other monomers through a process of plastic de-polymerization.

Nothing else like it.

Hydroxy Systems offers significant benefits over the competition across the board.

-

Our technology stands out by its ability to accept a wide spectrum of plastic waste, including soft, hard-to-recycle, mixed, unwashed, and unsorted plastics. This unparalleled versatility ensures that even the most challenging plastic materials can be transformed into valuable resources.

-

Unlike other recycling methods that often emit harmful pollutants, we take pride in our emissions-free process. Our state-of-the-art plants are designed with sustainability in mind, with no need for chimneys or exhaust systems. This commitment to environmental responsibility ensures that our technology is not just groundbreaking but also eco-friendly.

-

Our modular and scalable design allows for rapid deployment, setup, and functionality. Whether it's a small-scale operation or a large industrial plant, our technology can be tailored to fit the specific needs of any project. This unmatched scalability ensures that we can swiftly address the plastic waste crisis on a global scale.

Intelligent Algorithms

Intelligent AI Algorithms drive our Advanced Recycling process, adjusting system settings based on the type and composition of plastics used. This ensures consistent output with every cycle, while facilitating independent operation.

Pollution-Free

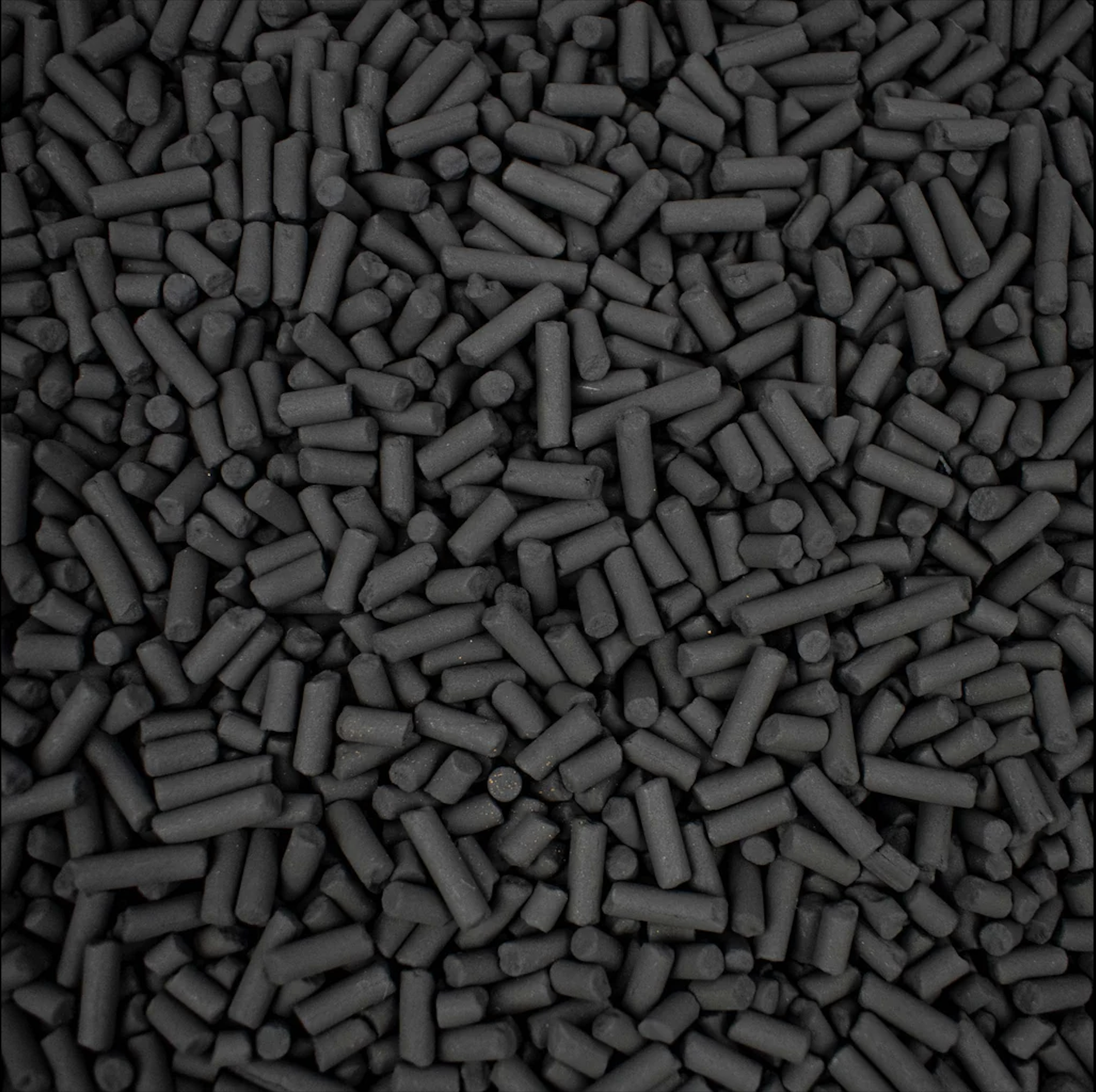

Unlike other approaches, our process produces zero emissions, eliminating the need for even a chimney at our plants. But our innovation doesn't stop there: the technology leaves behind carbon once the cycle concludes. This carbon is then utilised as a soil enhancer or transformed as per other industrial applications.

Engineering at its best.

Modular and Scalable

Our modular and scalable ensures quick deployment and seamless integration into any recycling facility, while effortlessly adapting to increasing demands and capacities.

Silent Operation

Say goodbye to noise pollution; our operations are virtually silent, prioritising desirable working conditions in industrial environments.

No Moving Parts

Our durable plant construction contains no moving parts, minimising maintenance needs and ensuring consistent performance

Safe Working Environment

Operating at atmospheric pressure, and with heat generated from electricity instead of combustion, our plants prioritise safety by eliminating fire and pressure related risks.

“I believe our technology will not only redefine how we perceive and handle plastic waste, but will also serve as the bedrock for a truly circular economy...”

— Konda Reddy, Director